Thaum kev tsim khoom tsheb hloov zuj zus mus rau qhov kev tsim khoom yooj ywm thiab ntse heev, muaj kev xav tau sai rau cov kab ntau lawm rau cov kev daws teeb meem automation nrog kev hloov pauv ib puag ncig zoo dua thiab kev ua haujlwm ntau yam. Nrog lawv cov duab zoo li tib neeg thiab kev txav mus los, cov neeg hlau zoo li tib neeg yuav tsum ua cov haujlwm xws li kev tshuaj xyuas txawb thiab kev sib dhos zoo - cov haujlwm uas cov neeg hlau lag luam ib txwm muaj teeb meem ua haujlwm hauv cov chaw sib dhos kawg. Qhov no ua rau lawv yog qhov tseem ceeb hauv kev txhim kho kev ywj pheej thiab kev ua haujlwm zoo ntawm cov kab ntau lawm.

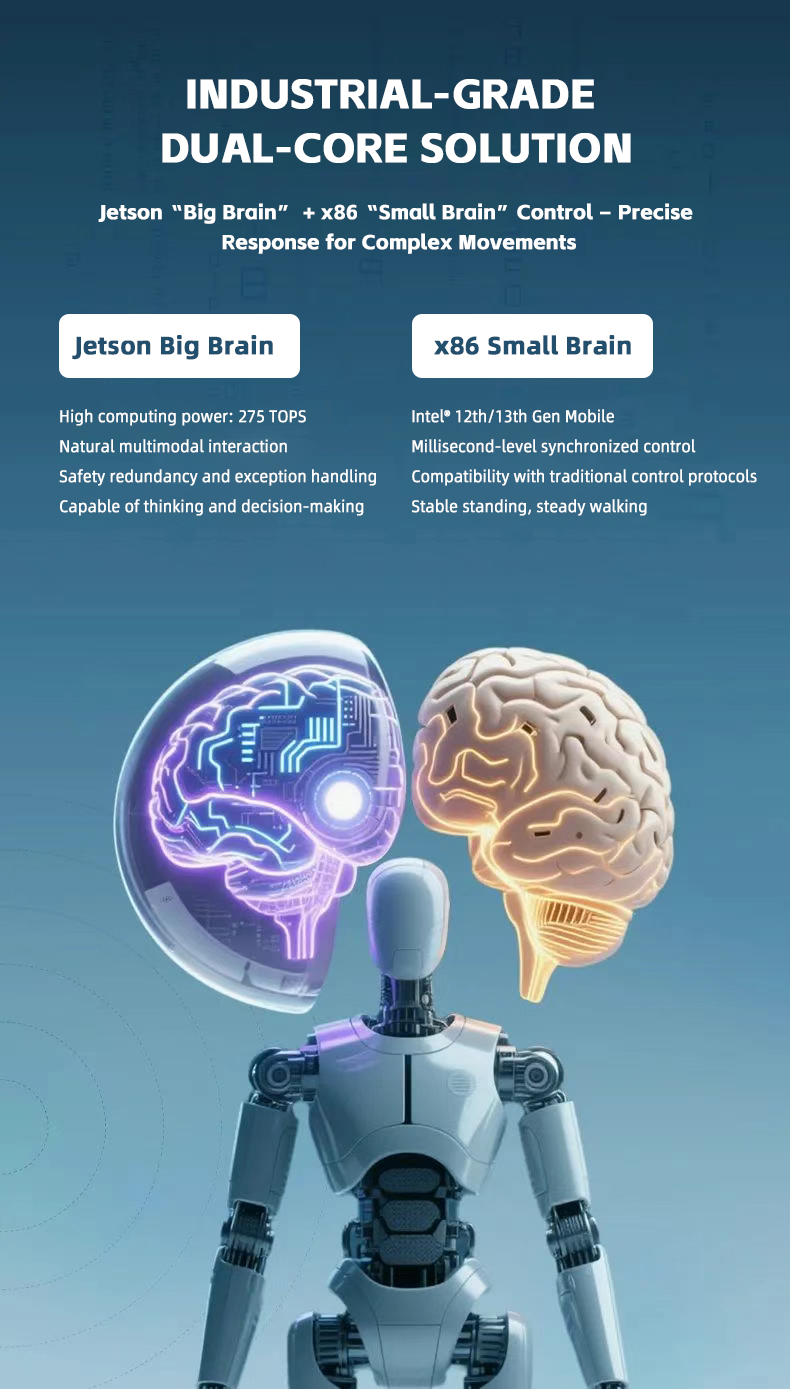

Nyob rau hauv qhov teeb meem no, APQ tau tshaj tawm KiWiBot30 core dual-brain solution, uas ua rau cov neeg hlau humanoid muaj peev xwm ua tiav cov haujlwm siab hauv cov xwm txheej sib dhos kawg ntawm lub tsheb. Cov kev daws teeb meem no txhawb nqa cov tshuab pom kev ua tiav qhov tseeb ntawm millimeter-level weld seam defect detection. Tib lub sijhawm, los ntawm kev tswj hwm ntau-axis, nws ua rau muaj kev tuav thiab tso qhov chaw meej. Piv nrog cov neeg hlau lag luam ib txwm muaj rau cov chaw nres tsheb ruaj khov thiab cov kev pab cuam preset, cov tshuab uas muaj KiWiBot30 core dual-brain qhia txog qhov ua tau ntawm kev tshuaj xyuas mobile autonomous thiab kev sib dhos yooj ywm, muab txoj hauv kev tshiab los daws cov teeb meem ntawm kev tsim khoom ntse yav tom ntej.

Cov Teeb Meem Mob Ntawm Kab Ntau Lawm: Qhov Chasm Kev Ua Haujlwm Ib Txwm Tsis Tuaj Yeem Hla Dhau

Hauv kev tsim khoom siab heev, kev tshuaj xyuas zoo thiab kev sib dhos yooj ywm tau dhau los ua qhov teeb meem tseem ceeb hauv kev txhim kho kev lag luam. Piv txwv li, kev tsim khoom tsheb, kev tshuaj xyuas lub cev vuam yuav tsum tau txheeb xyuas cov qhov tsis zoo hauv qib micron, thiab kev sib dhos qhov tseeb yuav tsum tau tswj hwm ntau txoj kab sib koom ua ke. Cov khoom siv ib txwm muaj ntsib peb qhov teeb meem loj:

-

Kev Teb qeeb:Kev pom thiab kev ua haujlwm txav mus los muaj kev ncua sijhawm ntau pua milliseconds, ua rau poob kev ua haujlwm ntawm cov kab ntau lawm ceev ceev.

-

Lub Hwj Chim Xam Fragmented:Kev pom, kev txiav txim siab, thiab kev tswj kev txav mus los raug sib cais, tsis muaj peev xwm txaus rau kev ua cov ntaub ntawv multimodal.

-

Kev Txwv ntawm Qhov Chaw:Lub cev ntawm lub tshuab muaj qhov chaw teeb tsa tsawg heev, ua rau nws nyuaj rau kev siv cov tswj hwm ib txwm muaj.

Cov teeb meem no yuam kom cov tuam txhab txo qhov ua tau zoo los ntawm kev ntxiv cov chaw nres tsheb lossis siv nyiaj ntau lab daus las rau kev txhim kho cov kab ntau lawm. Kev xa cov neeg hlau ntse uas muaj lub cev nrog cov tswj hwm tiam tom ntej ntawm cov kab ntau lawm muab cov lus cog tseg ntawm kev tawg qhov kev tsis sib haum xeeb no.

Kev Koom Tes Ua Ke ntawm Ob Lub Hlwb: Tus yuam sij rau Kev Teb Rov Qab Qib Millisecond

Nyob rau thawj ib nrab ntawm xyoo 2025, Apuqi cov khoom KiWiBot series feem ntau tshwm sim ntawm cov rooj sib tham loj robotics. Lub cuab yeej me me no siv lub tswv yim tshiab dual-brain:

-

Jetson Lub Hlwb Pom Kev:Muab 275 TOPS ntawm lub zog suav, muaj peev xwm ua tiav plaub txoj kab ntawm cov kwj deg pom kev siab hauv lub sijhawm tiag tiag, txhawb kev tshuaj xyuas qhov tsis zoo ntawm cov kab tsheb.

-

x86 Lub Hlwb Kev Txav Mus Los:Paub txog kev tswj hwm ntau txoj kab sib koom ua ke, txo cov lus txib jitter mus rau qib microsecond, txhim kho kev ua haujlwm zoo thiab kev sib dhos meej.

Ob lub hlwb sib txuas ua ke los ntawm cov channel ceev ceev los tsim kom muaj lub kaw lus "kev pom-kev txiav txim siab-kev ua haujlwm". Thaum lub kaw lus pom kev pom kev sib dhos, lub kaw lus txav tuaj yeem ua qhov kev hloov kho tam sim ntawd, ua tiav qhov kev sib koom tes "qhov muag rau tes".

Kev Txheeb Xyuas Zoo: Kev Ntseeg Tau Zoo Hauv Qib Kev Lag Luam Los Ntawm Kev Sim Dua

Los ntawm kev sim ntau yam, KiWiBot30 qhov kev ua tau zoo tau mus txog cov qauv qib quasi-automotive, qhia txog kev ua tau zoo thiab kev ruaj khov:

1. Lub motherboard yog coated nrog peb-pov thawj tiv thaiv txheej kom tiv taus roj av xeb.

2. Lub tshuab cua txias uas muab tso rau hauv lub tshuab no txo qhov ntim ntawm lub tshuab los ntawm 40% thaum tseem ua tau zoo ib yam.

3. Kev kuaj xyuas npog cov xwm txheej hnyav xws li qhov kub thiab txias hloov pauv ntau, kev poob siab, thiab kev co.

Ntsib lub nthwv dej ntawm kev tsim khoom tsheb txav mus rau qhov muaj kev ywj pheej thiab kev txawj ntse siab, Apuqi nkag siab tob txog lub hom phiaj tseem ceeb uas cov kab ke tswj hwm tseem ceeb ntawm cov neeg hlau ntse uas muaj lub cev.

Ua ib lub tuam txhab muab kev pabcuam kho vajtse thiab software rau "core dual-brain" ntawm cov neeg hlau ntse embodied, Apuqi yeej ib txwm ua raws li kev coj noj coj ua ntawm lub tuam txhab ntawm "Txhim khu kev qha, thiab Yog li ntawd ntseeg siab." Peb txuas ntxiv txhim kho thaj chaw ntawm kev txawj ntse embodied, tsom mus rau kev tsim cov platform kho vajtse ruaj khov, txhim khu kev qha thiab cov txheej txheem software ua haujlwm zoo. Peb txoj kev cog lus yog muab rau peb cov neeg siv khoom nrog cov kev daws teeb meem puv ntoob uas npog txhua yam los ntawm kev tswj hwm tseem ceeb mus rau kev koom ua ke, ua tiav los ntawm kev tshaj lij thiab cov kev pabcuam zoo tshaj plaws. Ua ke nrog peb cov neeg koom tes, peb siv zog los tsav kev tsim kho tshiab thiab kev siv cov neeg hlau humanoid hauv kev tsim khoom tsheb thiab cov ntawv thov kev lag luam dav dua. Nrog lub hauv paus thev naus laus zis txhim khu kev qha, peb txhawb nqa yav tom ntej ntawm kev tsim khoom ntse.

Yog tias koj xav paub txog peb lub tuam txhab thiab cov khoom lag luam, thov hu rau peb tus neeg sawv cev txawv teb chaws, Robin.

Email: yang.chen@apuqi.com

WhatsApp: +86 18351628738

Lub sijhawm tshaj tawm: Lub Xya Hli-03-2025