The semiconductor industry is a typical high-precision, high-continuity sector, where production equipment must operate year-round without interruption, imposing stringent demands on the stability, reliability, and data security of industrial control devices. A domestic manufacturer specializing in semiconductor wafer transfer automation equipment has established an in-depth collaboration with APQ. Based on the E7 embedded industrial control platform, the deployment of its wafer sort machine control core was completed rapidly, significantly improving project response and equipment manufacturing efficiency.

01

Customer background and challenges

Company Profile:

A leading domestic supplier of semiconductor automation equipment, specializing in the research, development, and manufacturing of semiconductor wafer transfer automation equipment. Committed to the localization of wafer transfer equipment and core components, with products widely used in multiple well-known wafer manufacturing plants, advanced packaging lines, compound semiconductor manufacturers, and emerging industries such as Micro LED.

Core pain point

•The equipment stability requirement is extremely high: the semiconductor manufacturing environment needs to meet the requirement of uninterrupted operation 24/7. Any unplanned downtime may result in the scrapping of the entire batch of wafers, causing significant losses.

•Data security and inconvenient maintenance: Although multi-hard disk backup is common, traditional industrial PCs require disassembly for hard disk replacement, resulting in a short maintenance window and complex operations.

•Limited scalability: The device needs to be connected to multiple data acquisition cards and industrial cameras, but traditional compact industrial computers lack sufficient expansion capabilities.

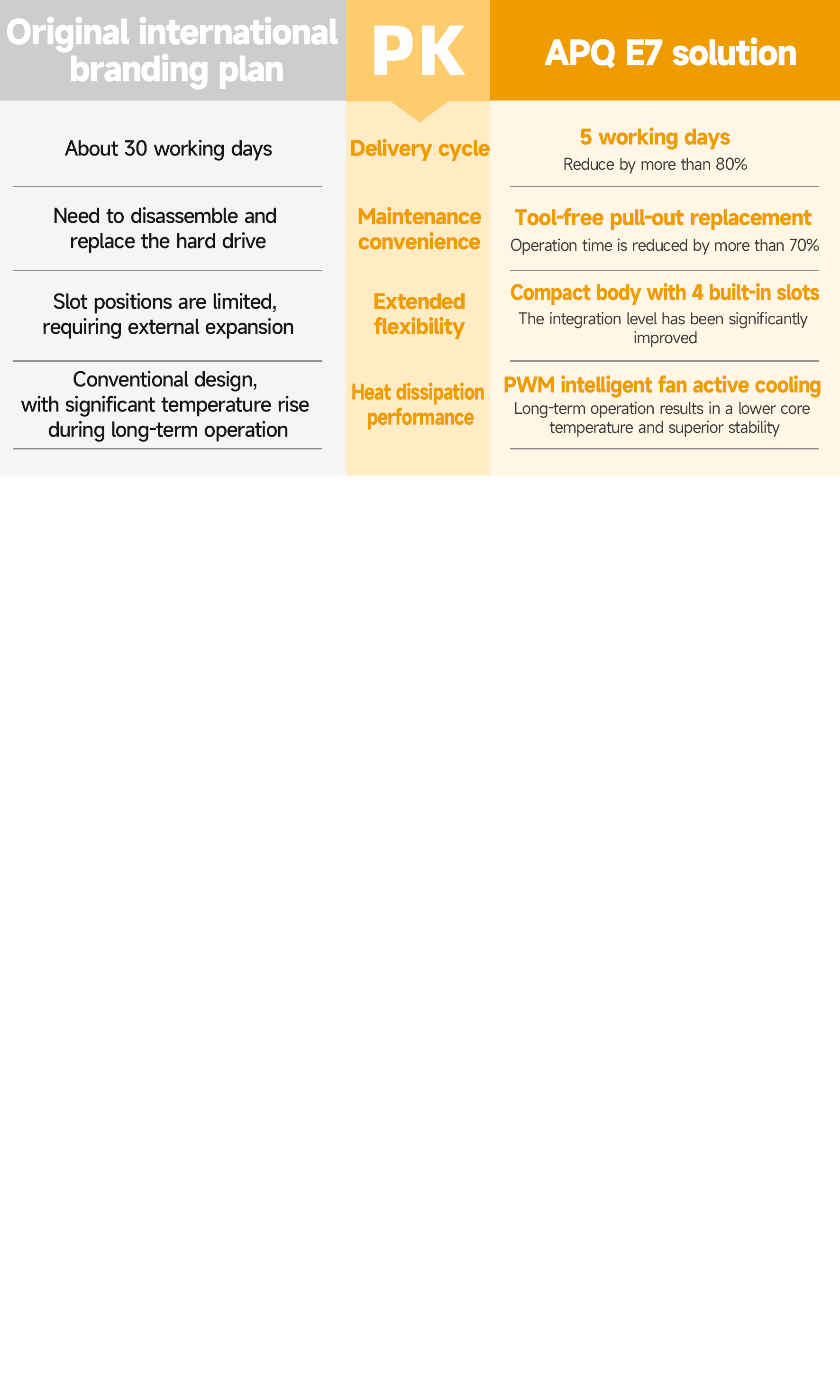

•Long delivery cycle: In the past, when major international brands were used, the delivery cycle was about 30 working days, which affected the customer's production line deployment and update pace.

02

APQ Solution: E7 high-reliability embedded industrial PC

Product highlights

• Efficient computing platform: Equipped with Intel® Q670 chipset, it supports i7-12700 processors, ensuring efficient execution of complex control tasks.

• Multiple data protection: Equipped with dual 1TB SSD, supporting RAID 0/1 modes, it achieves data redundancy and high-speed storage, effectively preventing data loss.

• Strong scalability: Provides 4 expansion slots (2×PCIe x16 + 2×PCI), allowing easy access to multiple data acquisition cards and function boards.

• Diverse industrial interfaces: Integrated with 6 RS232 ports (2 of which support 422/485), 6×USB3.0, and dual Gigabit Ethernet ports, fully compatible with various industrial peripherals.

• Highly reliable power supply: 240W wide-voltage power module, supporting 9–36V DC input, with power redundancy management capability.

• Compact and seismic-resistant structure: All-metal body, supporting multiple installation methods such as VESA, wall-mounting, and desktop, adapting to the space constraints of semiconductor workshops.

Service Advantages:

• Rapid delivery: Leveraging a mature supply chain and flexible production model, we can quickly complete production testing and shipment.

• Flexible customization: Supporting a drawer-style design for storage modules, allowing for quick replacement of hard drives without disassembly, significantly enhancing maintenance efficiency.

• Full-process technical support: From scheme selection, configuration customization to on-site debugging, we provide professional assistance and rapid response throughout the entire process.

03

Key achievements: Dual improvement in reliability and operational efficiency

Improvement in performance and reliability

• System stability: No malfunction during continuous 7×24-hour load testing, with a significant improvement in MTBF, fully meeting the operational requirements of semiconductor production lines.

• Data security: RAID 1 configuration ensures real-time mirroring of production data, preventing data loss due to single disk failure.

• Maintenance efficiency: The drawer-style hard drive design significantly reduces replacement time and makes operation more convenient.

• Scalability: Multiple expansion slots allow customers to simultaneously connect up to four high-performance acquisition cards, significantly enhancing system integration.

04

Customer feedback

Evaluation by the customer's technical director

"APQ E7 embedded industrial PC not only delivers extremely fast, but also boasts solid heat dissipation and structural workmanship, truly addressing the pain points we encounter in equipment production. Compared to the international brands we previously used, APQ has shortened the delivery cycle from 30 days to 5 days while ensuring the same level of reliability.Their response speed and technical support are also of high standard. Now, they can not only ship products quickly but also flexibly adjust configurations according to our needs, giving us stronger responsiveness and cost advantages in market competition."

05

Core strengths of APQ E7 Series

• Ultimate reliability: Industrial-grade components, wide temperature and voltage design, and efficient heat dissipation ensure stable operation 24/7.

• Flexible expansion: Provides multiple PCIe/PCI expansion slots within a compact size to meet complex peripheral access requirements.

• Convenient maintenance: The pull-out hard drive design and modular architecture greatly enhance on-site maintenance efficiency.

• Rapid delivery: With robust supply chain management and production systems, we support swift shipment of standard products and promptly respond to urgent customer needs.

• In-depth support: Provides comprehensive professional technical services covering the entire process from model selection consultation, customized configuration to on-site debugging.

In the process of semiconductor manufacturing moving towards higher automation and intelligence, the reliability, scalability, and delivery efficiency of industrial control main control units have become key competitive advantages for equipment manufacturers. The APQ E7 series, through its highly reliable hardware design, flexible expansion architecture, and rapid delivery services, not only helps customers achieve cost optimization and accelerated delivery, but also verifies the reliability and applicability of domestic industrial control equipment in the high-end manufacturing field. APQ will continue to deeply explore industrial intelligence and provide a more solid and agile edge computing foundation for industries such as semiconductor manufacturing.

Post time: Jan-22-2026