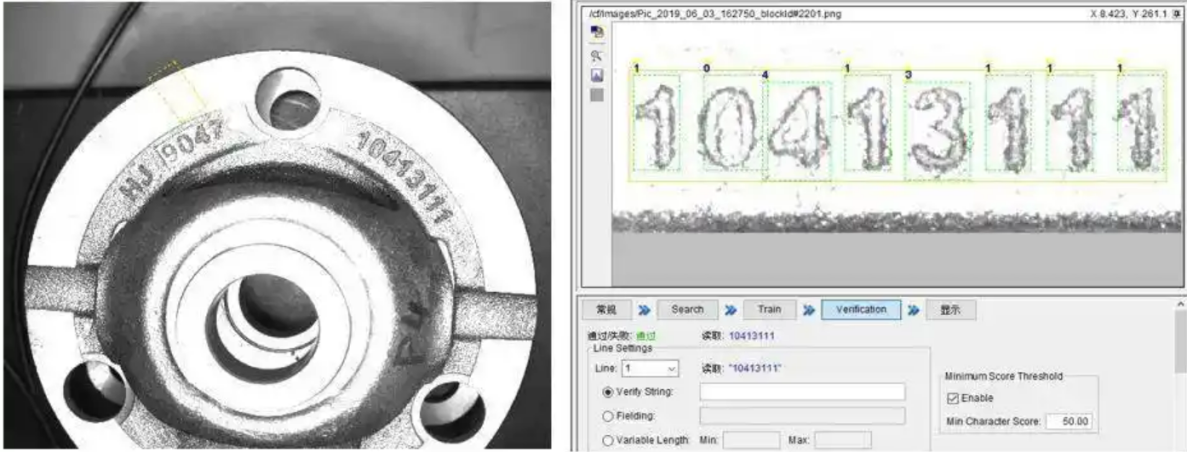

In modern industrial production, OCR (Optical Character Recognition) technology is increasingly being applied across industries such as food packaging, new energy, automotive manufacturing, and 3C electronics. It assists companies in automatically identifying product codes, production dates, batch numbers, and other character information, playing a key role in preventing product reputation damage caused by defects or labeling errors. With the emergence of complex character combinations, changes in printing techniques, and material variations, the industry is adopting new machine vision technologies to ensure high-precision, high-efficiency, and high-stability real-time detection of printed characters.

High Standards for Industrial PCs in OCR Applications

Modern OCR detection applications demand that the industrial PC, serving as the core control unit, meets high standards in multiple dimensions to cope with the challenges of real-time performance, accuracy, and stability in complex industrial environments.

1. High Computing Power and Real-Time Processing Capabilities

Rapid response capability: The system must support real-time analysis of high-resolution images and execution of deep learning models during OCR detection. For instance, on high-speed production lines, it must be capable of recognizing thousands of characters per minute.

2. Hardware Compatibility and Expandability

Multiple device interfaces: Supports simultaneous triggering of multiple cameras, is compatible with various industrial communication protocols, and can interconnect with PLCs and robotic arms to enable automated sorting or alarm triggering based on OCR results.

Rich expandability: Easily integrates GPU accelerator cards or FPGA modules to meet varying computational needs.

3. Environmental Adaptability and Reliability

Designed to withstand high temperatures, humidity, and dusty industrial environments.

Features strong vibration and interference resistance.

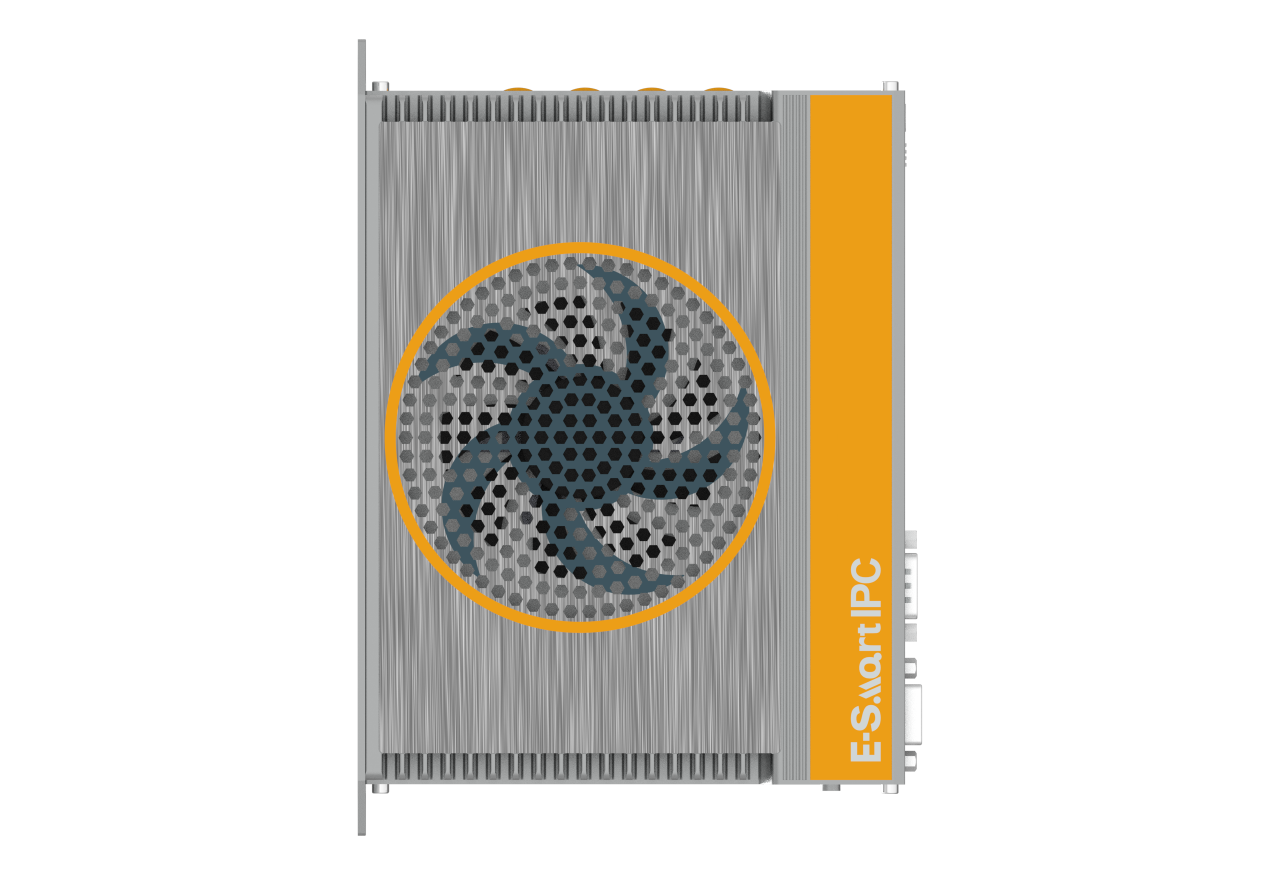

AK7’s Advantages in Machine Vision

APQ’s AK7 magazine-style industrial controller offers an outstanding price-performance ratio for machine vision applications. It supports Intel 6th to 9th Gen desktop processors with powerful data processing capabilities. Its modular design enables flexible expansion, such as control cards or camera acquisition cards. The auxiliary magazine supports 4 channels of 24V 1A lighting control and 16 GPIOs, making AK7 an ideal and cost-effective solution for projects with 2–6 cameras. It efficiently processes large volumes of data and ensures high-speed inspection, providing a reliable hardware solution for cutting-edge OCR detection technologies.

High-Performance Architecture of AK7

The AK7 magazine-style smart controller comes with 8GB DDR4 memory and 128GB industrial-grade SSD storage. It delivers a high-performance computing structure capable of parallel execution of intelligent vision algorithms. The hardware interface follows strict industrial automation standards. Dual gigabit Ethernet ports (supporting GigE Vision) enable low-latency data transmission with high-frame-rate industrial cameras. Four USB3.1 Gen2 ports support multi-spectral imaging devices. Dual RS-485/232 combo COM ports ensure compatibility with mainstream PLC communication protocols.

Lighting Magazine Expansion for Imaging Optimization

An optional lighting magazine expands 4 lighting control ports, compatible with ring lights, coaxial lights, and other industrial lighting types, ensuring imaging quality on complex surfaces (e.g., reflective packaging or curved labels) during OCR detection.

The magazine also includes an 8-in/8-out digital I/O module, enabling millisecond-level closed-loop response with sensors and sorting mechanisms on the production line, meeting functional safety requirements.

Additional Strengths of AK7

-

Compact fanless design saves space, reduces operational noise, and enhances overall reliability.

-

Strong environmental adaptability and wide temperature tolerance allow stable operation in harsh industrial settings.

-

Data protection features include supercapacitor support and HDD power backup to protect important data in sudden power loss events.

-

Powerful communication capabilities with support for EtherCAT bus ensure high-speed, synchronized data transmission between barcode readers, cameras, lights, and other peripherals.

-

With APQ's self-developed IPC+ toolkit—IPC Assistant—the AK7 supports autonomous operation, integrated fault diagnostics, and alerting systems to monitor the status of the controller, reader, camera, and lighting in real time, allowing quick resolution of issues like disconnection or overheating.

Conclusion

Today, OCR detection technology is widely used in logistics, finance, healthcare, manufacturing, transportation, and retail. Its deployment significantly reduces labor costs, improves processing efficiency, and provides critical data support for digital transformation. In complex scenarios, deep learning-based OCR algorithms combined with high-performance industrial controllers are accelerating industrial automation and the transformation of data into valuable assets. As the core hardware platform for OCR deployment, the computational power, interface compatibility, and stability of visual controllers directly impact system performance. APQ’s AK series E-Smart IPC flagship products offer highly reliable and adaptable hardware solutions for OCR applications, fulfilling our mission of “Making Industry More Reliable and Enabling a Better Life.”

If you're interested in our company and products, feel free to contact our overseas representative, Robin.

Email: yang.chen@apuqi.com

WhatsApp: +86 18351628738

Post time: Jul-15-2025