With the rapid popularization of intelligent robots today, the operational demands of robots in fire inspection, service reception, and warehousing and handling in complex environments are increasingly growing. These robots not only need to accomplish basic mobility tasks but also require intelligent capabilities such as environmental perception, real-time decision-making, and multi-robot collaboration. A reliable, high-performance, and adaptable controller has become the key to whether robots can be stably deployed across diverse scenarios.

In practical deployment, robot control systems often face three core challenges:

Computing power anxiety: AI tasks such as visual recognition, SLAM mapping, and path planning require extremely high computing power, and traditional controllers are unable to meet real-time response requirements;

Expansion bottleneck: There are various types of peripherals such as LiDAR, multi camera, ultrasonic sensors, 5G communication modules, etc., and the number and types of interfaces have become integration bottlenecks;

The environment is harsh: outdoor temperature differences, voltage fluctuations in industrial sites, dust vibrations, and other environmental factors pose a severe challenge to the long-term stable operation of equipment.

TAC-3000 Pro: Injecting an "all-in-one core" into robots

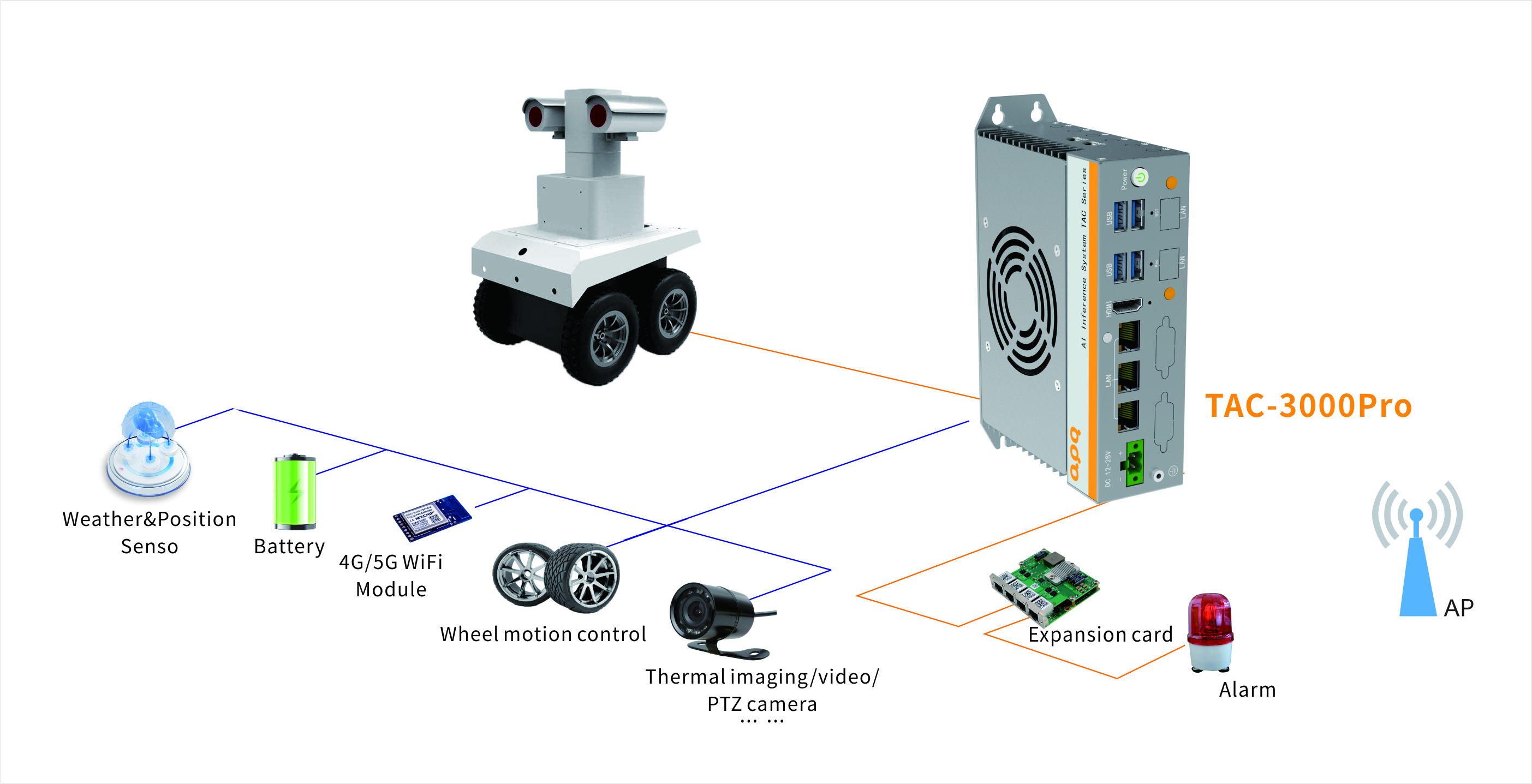

The APQ TAC-3000 Pro is centered around "strong computing power, multiple interfaces, high reliability, and easy integration", providing robots with a truly industrial grade intelligent control base:

Powerful computing platform: equipped with NVIDIA ® Jetson Orin Nano/NX series module, supports Super mode, with up to 157 TOPS AI computing power, easily capable of handling high load tasks such as navigation and obstacle avoidance, visual recognition, motion planning, etc;

Rich expansion interfaces: Provides 3 x Gigabit Ethernet ports, 4 x USB, 1 x HDMI, supports 4 x RS232/RS485, CAN FD, GPIO and other extensions, compatible with 5G/4G, Wi Fi extensions, and easy access to multiple types of sensors and communication modules;

Durable and reliable design: Supports 12-28V wide voltage DC input, operating temperature range of -20 ℃~60 ℃, all metal body and active fan heat dissipation, suitable for industrial environments such as vibration and high humidity;

Flexible installation method: Supports DIN rail and hanging ear installation, compact size (150.7 × 114.5 × 45mm), easy to integrate into various robot structures.

A smarter, more integrated, and more reliable robot experience

- High computing power supports precise navigation, dynamic obstacle avoidance, and real-time environmental monitoring, improving the accuracy and response speed of robot operations;

- Multi interface design reduces external switching and expansion costs, accelerates system integration and debugging cycles;

- The wide temperature and pressure range, as well as the sturdy structure, ensure the long-term stable operation of the robot in scenarios such as firefighting, inspection, and outdoor AGVs, reducing maintenance frequency.

The APQ TAC-3000 Pro is not just a hardware controller, but also a "capability platform" for robot intelligence and multi scenario development. It helps robots operate stably and efficiently in complex environments through high-performance computing, flexible scalability, and industrial grade reliability, assisting enterprises in accelerating the transition of robots from "mobile" to "intelligent" and from "single point trial" to "scale deployment".

Post time: Dec-25-2025